LEV for Spray Booths: The Essential Component for Industrial Safety and Compliance

Local Exhaust Ventilation (LEV) systems serve as an indispensable ally in maintaining a safe and health-conscious work environment, particularly within the context of spray booths often utilised across diverse industries. As imperative as the integration of LEV systems is, an intricate understanding of its significance, functionality, and maintenance is essential for entities that aim to not only preserve the well-being of workers but also adhere to regulatory standards set forth by health and safety guidelines in the UK.

Understanding LEV for Spray Booths

LEV for spray booths is designed to capture and carry away airborne contaminants at the source, thus protecting the breathing zone of operatives. These contaminants can include paint overspray, solvent fumes, and other volatile organic compounds (VOCs) that are harmful to the human body and can pose significant risks when inhaled.

The principle of operation for LEV systems involves a meticulous setup that includes hoods, ducting, air cleaners, and fans. The hood acts as the capturing device over the point of contaminant generation. Ductwork then transports the contaminated air away from the worker, subsequently passing it through filtration systems that remove the hazardous substances, thereby releasing cleaner air back into the atmosphere or recycling it within the workplace compliantly.

The Significance of LEV in Spray Booths

In contexts where employees are regularly involved with spray painting or coating applications, the importance of LEV cannot be understated. LEV for spray booths is not solely a matter of ensuring worker safety but also a legal requirement under the Control of Substances Hazardous to Health (COSHH) regulations. These laws mandate the control of exposure to hazardous substances to prevent ill health across all industrial sectors in the UK.

The installation of an efficient LEV system for spray booths in compliance with COSHH guidelines helps in:

- Mitigating health risks associated with the inhalation of toxic fumes.

- Reducing the environmental impact by controlling the release of VOCs into the atmosphere.

- Ensuring compliance with workplace health and safety legislation.

- Maintaining a high standard of product finish by preventing contamination.

Key Considerations for Implementing LEV in Spray Booths

While acknowledgement of the importance of LEV systems is widespread, the precision in selecting and maintaining an appropriate system is equally crucial. Some of the critical factors include:

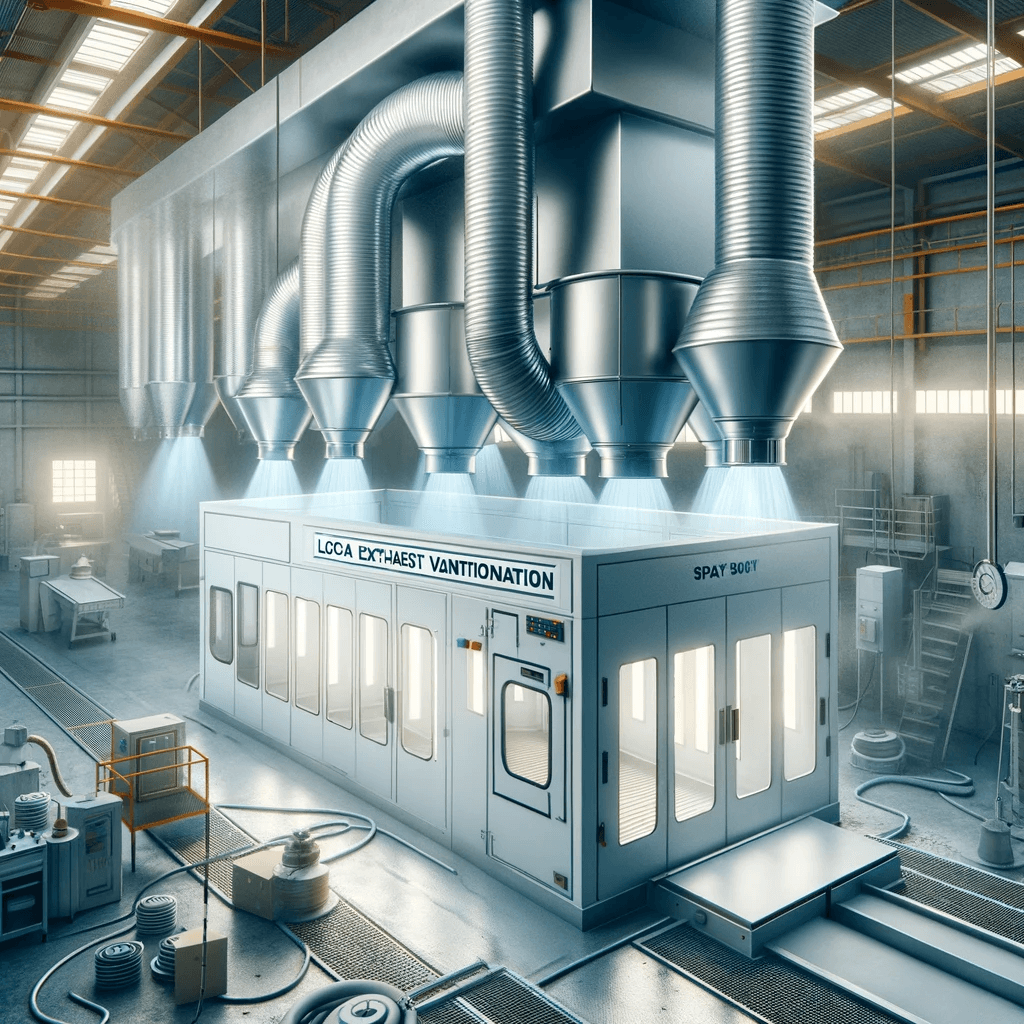

System Design and Efficiency

The LEV system for a spray booth must be tailored to handle the types of materials used, the frequency of spray operations, and the specific layout of the facility. This necessitates a bespoke design to ensure maximum capture of contaminants with minimal interference in the work process.

Regular Maintenance and Testing

As per the Health and Safety Executive (HSE) guidance, LEV systems should undergo thorough examination and testing at least once every 14 months to ensure they are functioning correctly. Failure to conduct regular maintenance can lead to reduced system efficiency and could expose workers to harmful air contaminants.

Training and Usage

Appropriate training must be provided to workers. This not only includes operation procedures but also recognition of the signs indicating a reduction in LEV performance, such as noticeable smells or visible dust.

The Role of WBT Services Ltd in Implementing LEV Systems

Though minimal reference to the client is requested, it is pertinent to establish the role of a trusted industrial systems provider such as WBT Services Ltd in delivering optimised LEV solutions across the UK. They are experts in the design, installation, and service of LEV systems tailored to meet the demands of each unique spray booth application. Their comprehensive understanding of industry-specific requirements, coupled with a commitment to safety and compliance, ensures the delivery of LEV systems that not only preserve worker health but also enhance operational efficiencies within any industrial workspace.

For further information on LEV systems and services offered by WBT Services Ltd, visit their website.

The Path to Compliance and Safety

Having an LEV for spray booths is not a mere installation project; it's an ongoing commitment to safeguarding the occupational health of workers while maintaining adherence to environmental and workplace regulations. As we advance technologically, the systems employed to manage workplace hazards must align not only with the evolving safety standards but also respond to the increased demand for sustainable operational practices.

In conclusion, LEV systems for spray booths are a crucial element in any industrial process where hazardous substances are present. They play a vital role in not only protecting workers' health but also ensuring the legal compliance of businesses operating within the UK. The effectiveness of LEV systems depends on their proper design, regular maintenance, and the competency of operators, all of which contribute to a safer and more productive working environment.

Choosing an experienced provider like WBT Services Ltd, companies can access bespoke LEV solutions that meet their specific needs and ensure their operations are both safe and compliant. As industry standards continue to evolve, keeping abreast of the latest developments in LEV technology and regulations will be key to maintaining a competitive advantage while prioritising the well-being of employees.