Preparing Your Workspace for LEV Installation

Welcome to an essential guide aimed at preparing your workspace for Local Exhaust Ventilation (LEV) systems. As a comprehensive provider of industrial systems and solutions, WBT Services Ltd. understands the importance of an efficiently designed workspace that complies with health and safety regulations. This blog post will walk you through the vital steps required to ensure a successful LEV installation.

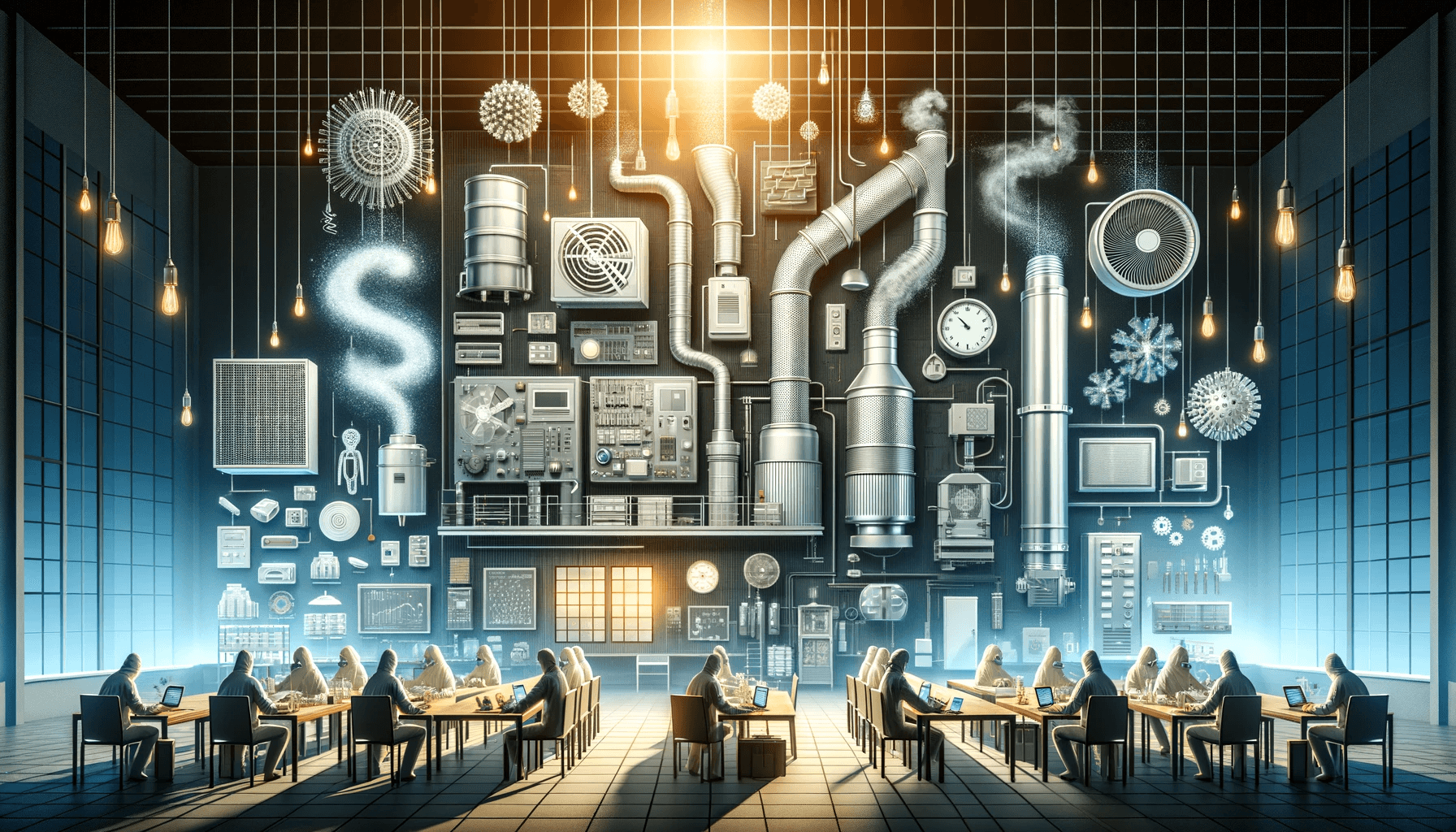

Understanding the Basics of LEV Systems

Before diving into the preparation process, it is crucial to understand what LEV systems are and their significance in your workspace. LEV systems are designed to protect workers by capturing airborne contaminants such as dust, mist, fumes, and vapour at the source, before these harmful substances enter the breathing zone. Ensuring you have an effective LEV system in place is not only a legal requirement but a moral obligation to safeguard your employees' health.

Initial Considerations

Before the LEV installation process begins, there are several key factors to consider:

Evaluate the types of contaminants present in your workspace.

Assess the processes generating these contaminants.

Determine the positioning of workstations relative to the contaminants.

These considerations will inform the type of LEV system that suits your needs and the installation approach to be taken.

Preparing the Workspace

Space Allocation

Ensure that there is adequate space in your work area for the LEV system components. You should clear the area of any unnecessary equipment or obstructions that might impede the installation process.

Assessing Infrastructure

Your workspace infrastructure is key to a successful installation. This includes evaluating existing electrical supplies, support structures, and access points. If modifications are needed, it’s crucial to address these well in advance.

Minimising Downtime

Installing an LEV system can disrupt normal operations. Plan for installation during downtime or schedule it in stages to minimise the impact on your daily workflow.

Collaboration with Installation Professionals

Working closely with experienced installation professionals is imperative. They can provide insights into the best practices for preparing your workspace and ensure the system complies with all necessary standards and regulations.

- Communicate your specific workspace needs and challenges.

- Discuss the timeline and scope of the installation process.

- Ensure that your staff understand their roles during the installation.

Professional installers will also guide you on future LEV testing and maintenance requirements.

Training and Awareness

It’s paramount to educate your workforce about the new LEV system. Proper training ensures that employees know how to use the system effectively and maintain it, which prolongs its lifespan and efficiency. Consider hosting training sessions that cover:

Operational procedures of the new LEV system.

Importance of LEV systems in maintaining workplace safety.

Maintenance routines and reporting any issues.

Post-Installation Checks and LEV Testing

Once the LEV system is installed, post-installation checks are vital to confirm that it operates as intended. This includes verifying airflow rates and capturing efficiencies. Additionally, regular LEV testing is not only a legal requirement but also a practice that ensures ongoing protection for your workforce.

Final Thoughts

Preparing your workspace for LEV installation is a process that requires careful consideration, planning, and collaboration with experts. By following the steps outlined above, you can facilitate a smooth installation and ensure a safe working environment. Remember, the health and safety of your employees are paramount, and an effectively installed LEV system is a significant component in achieving that goal.

For further assistance and expertise in LEV systems, reach out to WBT Services Ltd. Our team is dedicated to providing top-tier industrial solutions that meet your specific needs.

FAQs

What are LEV systems, and why are they important in a workspace?

Local Exhaust Ventilation (LEV) systems are designed to capture airborne contaminants at the source before they can enter the breathing zone of workers, thereby protecting their health. They are crucial for maintaining safe air quality in industrial environments and are a legal health and safety requirement.

What should I consider before installing an LEV system?

Prior to installation, you should evaluate the types of contaminants in your workspace, assess the processes generating these contaminants, and determine the positioning of workstations in relation to the contaminants. These factors will influence the selection and placement of your LEV system.

How can I prepare my workspace for LEV installation to ensure minimal disruption?

To prepare for LEV installation, clear any unnecessary equipment and obstructions from the area, assess and possibly upgrade your workspace infrastructure including electrical supplies and support structures, and plan the installation during downtime or in stages. Collaborating with installation professionals can also help streamline the process and reduce impact on daily operations.

Key Takeaways

- Before installing a Local Exhaust Ventilation (LEV) system, it's critical to understand its purpose—to protect employee health by capturing airborne contaminants—and the legal and moral imperatives behind its use. An initial assessment should determine the types of contaminants present, their sources, and the positioning of workstations relative to these contaminants. This assessment guides the choice of the LEV system and informs the installation approach.

- Effective preparation of the workspace is vital for a smooth LEV installation. This includes ensuring there is adequate space for the system, clearing any obstructions, evaluating and, if necessary, upgrading infrastructure such as electrical supplies and support structures, and strategically scheduling the installation to minimize disruption to operations. Collaborating with experienced installation professionals is recommended to tailor the setup to specific workspace needs and ensure compliance with standards.

- Education and training are essential components of the LEV installation process. Employees must understand how to operate and maintain the new system correctly, underscoring its role in workplace safety. Post-installation checks and regular LEV testing are mandatory to confirm the system's proper functioning and maintain ongoing protection for the workforce. These steps, along with expert collaboration and planning, contribute to a safer working environment and the longevity of the LEV system.