Custom LEV Design Challenges and Solutions

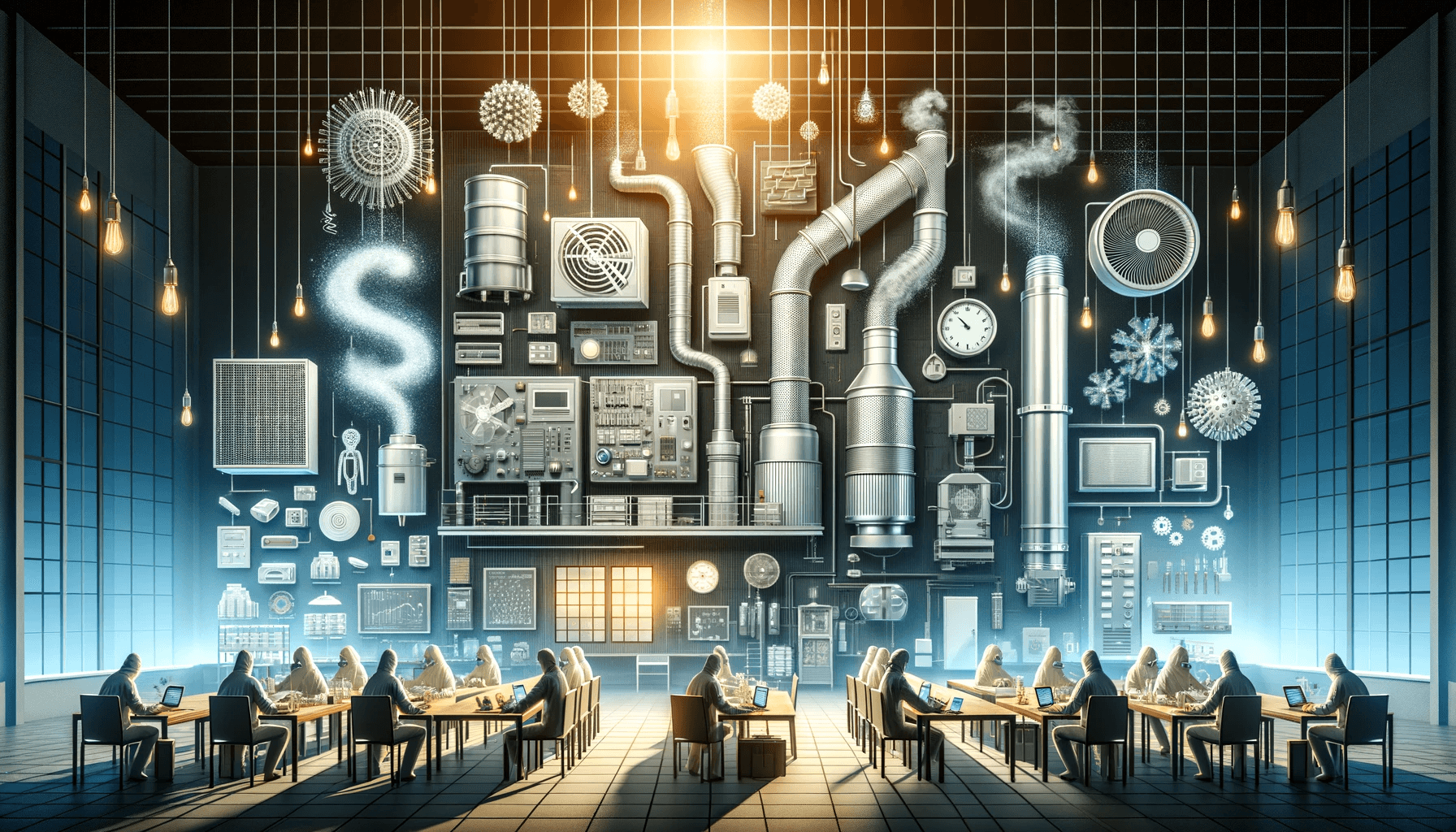

Introduction to LEV Systems

Local Exhaust Ventilation (LEV) systems are crucial for maintaining a safe working environment in numerous industrial settings. By effectively capturing and removing airborne contaminants at the source, LEV systems protect workers' health and ensure compliance with occupational health and safety regulations. As you seek out the ideal system for your operations, understanding the challenges and solutions in custom LEV design is paramount.

Identifying Your Specific Needs

Every workspace has unique demands and constraints, which is why a one-size-fits-all approach to LEV design is rarely sufficient. Your first step should always be a thorough assessment of the specific contaminants, processes, and layout of your facility. This would ensure that the LEV system is tailored to efficiently and effectively mitigate risks associated with hazardous substances.

Contaminant Characteristics

Understanding the type, quantity, and properties of the contaminants is essential. Whether dealing with dust, fumes, vapours, or gases, the LEV system must be designed to cope with the particular hazards they present.

Process Evaluation

Examine the processes that generate airborne contaminants. Consider the frequency, duration, and intensity of these operations to establish an LEV system that can operate continuously under such conditions without faltering.

Workplace Layout

The physical layout of your facility will significantly influence the design of your LEV system. Space constraints, worker mobility, and the location of contaminant sources must all be factored into the design process to ensure efficient contaminant capture and minimal interference with operations.

Common Design Challenges

When creating a custom LEV system, several challenges can arise. Addressing these challenges head-on with innovative solutions is key to ensuring your system is both effective and compliant.

Achieving Adequate Capture Velocity

One common issue is ensuring the capture hood design achieves sufficient velocity to draw in contaminants without being so forceful that it disrupts the work process. This requires a careful balance which can be met through precise engineering and airflow modelling.

System Flexibility

In industries where processes change frequently, LEV systems must be adaptable. This can include the need for reconfigurable ductwork or mobile units that can be moved as required.

Energy Efficiency

Power consumption is an ongoing operational cost that must be considered. Optimising the system for energy efficiency without sacrificing performance is a challenge that requires innovative design solutions.

Effective Solutions in LEV Design

LEV design must be approached with a problem-solving mindset. Here are some effective strategies to overcome the common challenges faced during the design phase:

Custom Hood Design

By customising the hood design to match the emission points precisely, one can ensure efficient capture of contaminants with lower energy expenditure.

Modular Ducting Systems

Employing modular ducting allows for easy reconfiguration of the LEV system, lending the flexibility needed to adapt to changing processes.

Variable Air Volume (VAV) Systems

VAV systems can adjust the airflow based on real-time demand, offering significant energy savings while maintaining the required contaminant capture efficiency.

Ensuring Compliance and Efficacy Through Testing

Once your custom LEV system is in place, it's crucial to validate its performance through LEV testing. This not only ensures compliance with regulations but also gives peace of mind that your workforce is protected. Regular testing and maintenance are non-negotiable for the continued effectiveness of your LEV system.

Why Choose Professional LEV Design Services

Partnering with experts in LEV design is the best way to ensure that your custom system addresses all challenges effectively. Professionals bring a wealth of experience and knowledge to the table, helping you navigate the complexities of custom design and offering solutions that are both innovative and compliant.

Conclusion

Designing a custom LEV system is a complex task that requires a deep understanding of the challenges and a commitment to finding effective solutions. By focusing on the specific needs of your operations, addressing design challenges head-on, and ensuring compliance through thorough testing, you can protect your employees and your business. With the professional guidance of seasoned experts, your custom LEV system will serve as a cornerstone of a healthy and productive working environment.

FAQs

What are the key factors to consider in custom LEV system design?

To ensure an effective LEV system design, it is critical to assess the specific contaminants, processes, and layout of your facility. This includes understanding the characteristics of the contaminants, evaluating the production processes generating these contaminants, and considering the physical workspace layout to design a system that provides efficient contaminant capture without impeding operations.

What are some common challenges when designing custom LEV systems, and how can they be overcome?

Design challenges include achieving adequate capture velocity, ensuring system flexibility, and optimizing energy efficiency. Overcoming these challenges involves precise engineering and airflow modelling for capture hood design, utilizing modular ducting for adaptability, and incorporating Variable Air Volume (VAV) systems to adjust airflow and save energy while maintaining performance.

Why is it important to have professional LEV design services, and what are the benefits of regular LEV testing?

Professional LEV design services bring expertise and experience to address the complexities of custom system design, ensuring that the solutions are both innovative and compliant with regulations. Regular LEV testing is essential to validate the system's performance, maintain compliance, and ensure the ongoing protection of your workforce's health.

Key Takeaways

The blog post highlights the importance of custom Local Exhaust Ventilation (LEV) system design, addressing specific workplace challenges, and ensuring worker safety in industrial environments. Here are three key takeaways:

1. Customization Is Critical: Effective LEV system design requires a detailed understanding of the unique characteristics of airborne contaminants, workplace processes, and the physical layout of the facility. A one-size-fits-all approach is insufficient as different workspaces have various needs that must be met to ensure the system effectively protects workers and complies with regulations.

2. Design Challenges and Solutions: The post identifies common challenges in custom LEV design, such as achieving the right capture velocity, ensuring system flexibility, and maximizing energy efficiency. These challenges can be tackled with specific design strategies, including precise airflow modelling for adequate capture velocity, using modular ducting for flexible configurations, and implementing Variable Air Volume (VAV) systems to optimize airflow based on demand, leading to energy savings while maintaining efficiency.

3. The Role of Professional Services and Testing: Engaging with professional LEV design services is crucial for navigating the complexities of creating an effective system that meets both safety and regulatory requirements. Additionally, regular LEV testing is emphasized as vital for verifying system efficacy, ensuring continued compliance, and safeguarding worker health. This ongoing assessment allows for prompt identification and correction of any issues, maintaining the integrity of the LEV system over time.