Optimal Local Exhaust Ventilation Design: Protecting Workers and Workplaces

In the realm of industrial settings, worker safety and adherence to stringent health regulations are of paramount importance. A critical element in achieving these aims lies in the effective implementation of a local exhaust ventilation (LEV) system. Locally sourced exhaust systems are specifically designed to capture and remove airborne contaminants at the source, preventing the spread of hazardous substances and ensuring a clean and safe working environment. The design of such systems requires meticulous planning, expert knowledge, and the adept application of engineering principles. This article provides insights into what underpins successful local exhaust ventilation design and its significance.

Understanding Local Exhaust Ventilation Design

Local exhaust ventilation design is a specialised field encompassing the devising of tailored solutions to combat air quality issues within various industrial sectors. These systems serve to extract harmful dust, vapours, gases, and fumes directly from their point of release, hence delivering a pivotal contribution to occupational health and safeguarding the environment.

A proficient LEV design necessitates a holistic understanding of aerodynamic processes, the physical and chemical characteristics of the contaminants, as well as ergonomic factors that might affect the way workers interact with the ventilation system. As air pollution within industrial environs is often unavoidable, the potency of local exhaust ventilation design lies in its capacity to efficiently and reliably remove these pollutants before they can permeate the broader workspace.

Key Principles in LEV System Design

The primary objective of a local exhaust ventilation system is to provide effective extraction. To that end, a range of critical factors must be considered:

Capture Efficiency

The design process starts with defining the optimal capture velocity — the required speed of airborne contaminants to be effectively drawn into the system. This depends on the contaminant's state and behaviour in the air. The design of the hood, the part of the system that captures the pollutants, plays a crucial role in ensuring this efficiency.

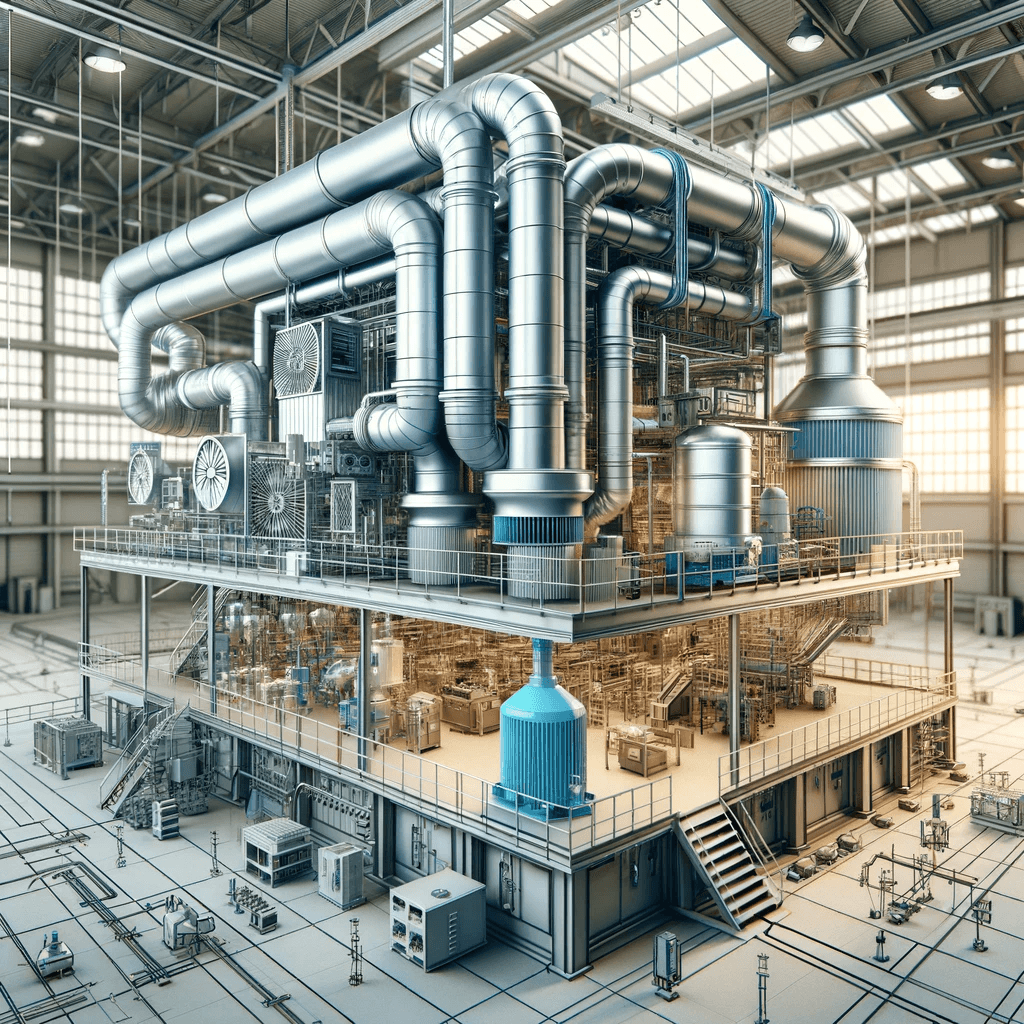

Ductwork Design

Properly dimensioned and smoothly contoured ductwork is essential for maintaining the integrity of airflow. The design must avoid sharp angles or unnecessary bends that could diminish air velocity or cause particle settlement, leading to blockages and system inefficiency.

Air Cleaning Devices

Depending on the nature of the contaminants, various air cleaning devices such as filters, scrubbers, or cyclones could be incorporated to purify the extracted air before it's either recirculated back into the workplace or released into the outside environment.

Airflow and Pressure Balancing

Ensuring balanced airflow within the LEV system is fundamental. This involves careful calculations to determine the fan size and motor power needed to maintain suitable extraction across all branches of the system — a critical step in maintaining consistent performance.

Noise Control

The design of the local exhaust ventilation system must also give due consideration to acoustic factors, minimising noise levels to protect workers' hearing and conform to noise regulation standards.

Implementing Your Local Exhaust Ventilation Design

Implementing a local exhaust ventilation design that fulfils its intended function without causing disruptive downtime or requiring extensive retrofitting is a multi-faceted challenge.

Assessment and Planning

The first step in successful LEV implementation is assessing the specific needs of the workplace. What types of contaminants are present? What processes are generating them? How are they released into the air? These questions form the basis for designing an effective and efficient system.

Design and Customisation

After the initial assessment, designers tailor the LEV system to the unique requirements of the facility. This means customising the hood design, duct layout, and selecting the right air cleaning technology to match the contaminants' characteristics.

Installation and Commissioning

With a robust design in place, skilled engineers then safely install the system, after which a meticulous commissioning process ensures that all components are working correctly and are finely tuned to the system's overall requirements.

Maintenance and Compliance

Post-installation, regular maintenance is crucial for ensuring the system operates at peak efficiency and remains compliant with relevant workplace regulations. This involves frequent inspections, filter replacements, and system adjustments as necessary.

WBT Services Ltd – Your Partner in Local Exhaust Ventilation Design

At WBT Services Ltd, our expertise extends across the spectrum of industrial systems and solutions. We are a UK-wide authority in creating customised local exhaust ventilation designs that not only meet but exceed the health and safety standards of today's demanding industrial environments. Our approach is meticulous, focused on providing solutions that are not just compliant but also sustainable and energy-efficient.

Our reserved, professional team is dedicated to crafting local exhaust ventilation designs that are tailored to each client's unique needs while ensuring minimal disruption to your operations. Our commitment to excellence in service provision is reflected in our meticulous attention to every aspect of local exhaust ventilation design, from initial assessments through to the maintenance and regular servicing we provide.

In conclusion, the careful design of a local exhaust ventilation system is a non-negotiable prerequisite in protecting workers and maintaining compliance with health and safety standards. By ensuring effective contaminant capture, designing precise ductwork, selecting appropriate air cleaning devices, and expertly balancing airflow, businesses can safeguard their workforce and their operations. With the assistance of WBT Services Ltd, your organisation can implement a local exhaust ventilation design that stands as a benchmark for industry excellence.

Whether you require the installation of a new system or the optimisation of an existing one, we invite you to harness our expertise in engineering a safer, cleaner, and more productive industrial environment.