Advantages of Local Exhaust Ventilation

When assessing the intricate network of safety measures within industrial environments, the significance of effective air quality management is paramount. Among various air purification strategies, Local Exhaust Ventilation (LEV) systems stand out as one of the most efficient methods for controlling the presence of airborne contaminants directly at their source. As specialists in safeguarding workplace environments, we would be remiss not to discuss the "advantages of local exhaust ventilation" crucial to industries across the UK.

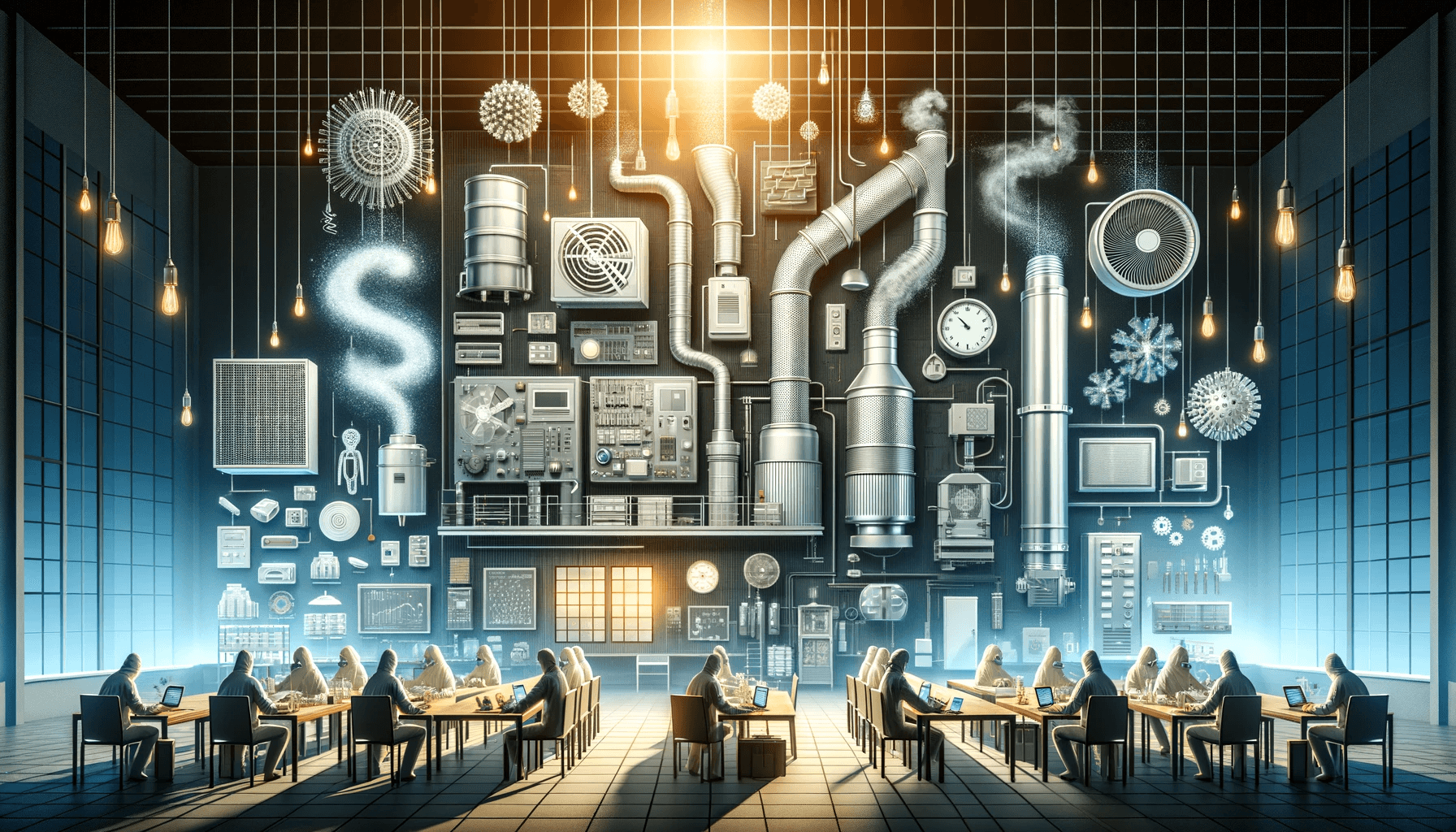

What is Local Exhaust Ventilation (LEV)?

Before we delve into the numerous advantages, it's essential to understand what LEV entails. Essentially, LEV systems are engineering controls designed to extract hazardous substances, such as dust, fumes, and vapours, away from the breathing zone of the workforce. These systems encompass extraction hoods, ducting, air cleaners, and exhausts, cumulatively acting to maintain the sanctity of the air within industrial premises.

The Advantages of Local Exhaust Ventilation

1. Health Protection of Employees

The primary benefit of LEV systems lies in their capacity to protect the health of employees. Prolonged exposure to harmful substances in the workplace can lead to a multitude of respiratory illnesses and chronic conditions. Through the targeted removal of pollutants, LEV systems reduce the risk of occupational diseases, thus upholding the well-being of the workforce.

2. Legal Compliance and Reduced Liability

In the UK, employers are bound by the Control of Substances Hazardous to Health (COSHH) regulations, which mandate the control of substances that can harm workers' health. Integrating LEV systems into an industrial facility's infrastructure not only aligns with legal requirements but also decreases the likelihood of facing penalties and liability claims associated with workplace-related health issues.

3. Enhanced Productivity

When employees are provided with a contaminant-free work environment, their productivity levels invariably rise. The absence of harmful particulates in the atmosphere equates to fewer health-related absenteeisms and a more focused, energetic, and efficient workforce.

4. Long-Term Cost Savings

While the installation of LEV systems might be perceived as an immediate expenditure, the long-term perspective highlights cost savings. By preventing workplace illness and reducing downtime, LEV systems contribute to continuous production cycles and avert expenses related to health care and legal issues.

5. Better Work Environment

The "advantages of local exhaust ventilation" extend to the general work environment. LEV systems help maintain a cleaner facility by limiting the spread of dust and debris. This not only contributes to a more pleasant work atmosphere but also safeguards machinery and products from contamination.

6. Energy Efficiency

Modern LEV systems are designed with energy efficiency in mind. By targeting specific contaminant release points and extracting pollutants at the source, these systems can operate with less energy than whole-room ventilation alternatives. This selective approach ensures that only the necessary amount of air is treated, reducing energy consumption and costs.

7. Customisation and Versatility

Another advantage is the versatility and customisation of LEV systems. They can be specifically designed to fit the particular needs of any work process or facility layout. Such tailored solutions ensure that all types of contaminants are managed effectively, regardless of industry-specific requirements.

8. Public Relations and Corporate Responsibility

A company's commitment to employee health and environmental standards can significantly influence its public image. By implementing LEV systems, companies demonstrate social responsibility and a proactive attitude towards environmental stewardship. This can enhance their reputation with customers, suppliers, and potential employees, adding to the corporate value.

9. Protecting the External Environment

The advantages of local exhaust ventilation are not limited to the confines of the industrial facility. Effective extraction and filtration of pollutants also mean that fewer contaminants are released into the external environment, aligning with broader environmental protection goals and regulations.

10. Ensuring Process Quality

Certain industrial processes require controlled environments to guarantee product quality. By removing airborne contaminants, LEV systems help maintain the integrity of these processes, thereby assuring the production of high-quality goods and services.

Implementing Local Exhaust Ventilation Systems

Embracing the "advantages of local exhaust ventilation" necessitates a strategic approach. It's quintessential for businesses, including those considering service providers like WBT Services Ltd (WBT Services Ltd), to work with seasoned professionals who can understand and deliver customised LEV solutions. From the design and installation to ongoing maintenance and regulatory compliance, a comprehensive approach ensures that the full spectrum of benefits is realised.

In conclusion, the integration of Local Exhaust Ventilation systems into industrial and commercial settings is vital for safeguarding health, optimising productivity, and sustaining environmental quality. While the awareness of the advantages may be increasing among business owners, it is the implementation of well-designed, energy-efficient and effective LEV systems that will truly revolutionise workplace safety and operational excellence. Given the potential long-term savings, legal compliance, and corporate responsibility implications, the case for investing in LEV systems is compelling and clear.